The Value of Sustainable and Eco-Friendly Chemical Products in Today's Market

The Value of Sustainable and Eco-Friendly Chemical Products in Today's Market

Blog Article

A Comprehensive Overview to Assessing Chemical Products for Ideal Integrated Solutions in Manufacturing and Beyond

In the significantly intricate landscape of manufacturing, the examination of chemical products stands as a pivotal consider attaining integrated remedies that focus on safety, performance, and sustainability. This thorough guide details vital elements such as governing conformity, item compatibility, and cost-effectiveness, all while emphasizing the significance of environmental stewardship. Comprehending these elements not just reduces risks however additionally positions companies for development and long-term growth. As we explore these essential components, the inquiry occurs: just how can these assessments be transformed right into workable approaches that propel your company onward?

Comprehending Governing Compliance

In the world of production, comprehending governing compliance is extremely important for ensuring both item safety and ecological security. Regulative structures, such as the Occupational Safety And Security and Wellness Management (OSHA) requirements and the Environmental Security Agency (EPA) policies, determine the risk-free handling, storage space, and disposal of chemical items. Compliance with these laws not just safeguards employees yet likewise reduces environmental effect and boosts a firm's track record.

Producers have to carefully evaluate the chemical substances they use, ensuring adherence to the pertinent security information sheets (SDS) and labeling needs, which supply important details pertaining to threats and risk-free usage. Remaining abreast of industry-specific policies, such as the Enrollment, Evaluation, Authorisation and Restriction of Chemicals (REACH) in Europe, is crucial for maintaining conformity and preventing potential legal implications.

Routine audits and training are necessary components of an extensive conformity approach, fostering a society of safety and recognition amongst employees. By prioritizing regulative compliance, suppliers can alleviate risk, enhance functional efficiency, and add to lasting techniques within the industry, inevitably bring about improved item top quality and client fulfillment.

Assessing Item Compatibility

Regulative conformity establishes the foundation for safe manufacturing methods, yet reviewing item compatibility is similarly vital for functional efficiency and security. Chemical Products. Item compatibility refers to the ability of different chemical materials to exist together without unfavorable interactions that could compromise the stability of processes or items. An extensive analysis begins with recognizing the chemical homes, including sensitivity, solubility, and security under different conditions

Manufacturers ought to carry out compatibility screening to recognize possible reactions that may take place when chemicals are combined or enter into contact with one an additional. This consists of evaluating factors such as temperature level variations, stress adjustments, and the presence of contaminations. It is also essential to take into consideration the impacts of materials made use of in containers, pipelines, and devices, as these can influence chemical behavior and efficiency.

Furthermore, suppliers must evaluate the possible impact of item compatibility on end-user applications. Inappropriate products can result in operational interruptions, item failures, and security hazards, which can damage online reputation and financial standing. A systematic technique to analyzing product compatibility not only improves operational performance however also ensures the safety and security and integrity of chemical items throughout their lifecycle.

Assessing Cost-Effectiveness

Evaluating cost-effectiveness is critical for makers aiming to maximize their chemical production procedures while maintaining productivity. This assessment starts with a detailed analysis of both straight and indirect costs related to chemical products. Direct prices encompass the acquisition price of chemicals, transportation, and storage space, while indirect costs may consist of labor, maintenance, and overhead expenses.

To successfully review cost-effectiveness, manufacturers must use a total expense of possession (TCO) strategy. This approach enables an extensive understanding of all expenses throughout the item lifecycle, from purchase to disposal. In addition, using efficiency metrics-- such as return rates and process effectiveness-- can give understandings into exactly how well chemical products add to overall production goals.

Benchmarking against market standards can additionally highlight possible locations for cost decrease or enhancement. By comparing their expenses and performance with competitors, suppliers can determine best methods and innovative remedies.

Moreover, involving suppliers in conversations about prices, quantity discounts, and long-lasting arrangements may generate desirable financial setups. Ultimately, a strategic concentrate on cost-effectiveness sustains not just productivity but likewise sustainability in the competitive landscape of chemical production.

Studying Environmental Influence

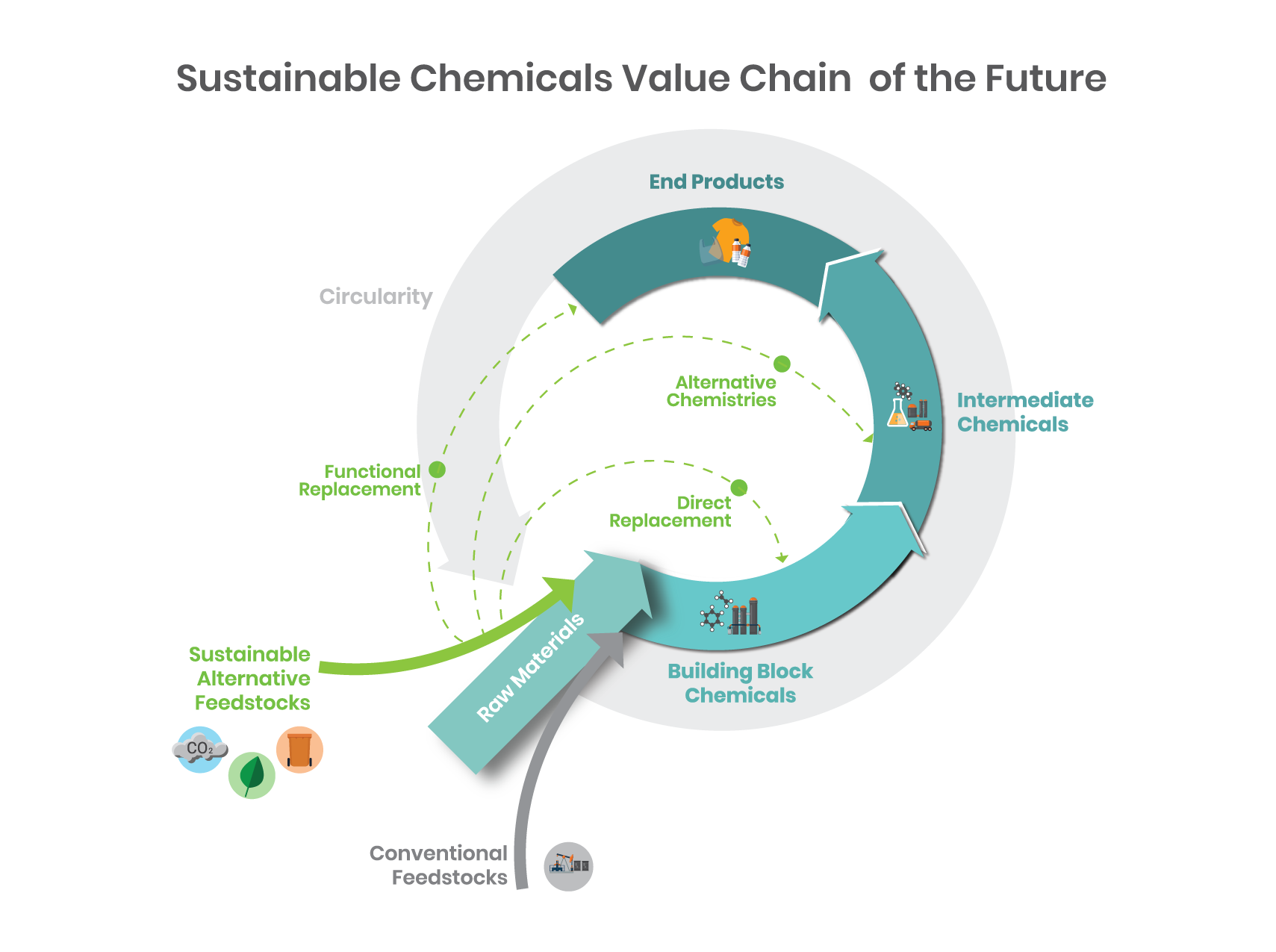

One crucial aspect is the selection of basic materials. Lasting sourcing can substantially lower adverse influences, as eco-friendly or much less unsafe products usually result in decrease emissions and fewer harmful byproducts. Furthermore, manufacturers should consider the effectiveness of their production processes; maximizing these can decrease waste and energy consumption.

Furthermore, item formula plays an important duty in figuring out ecological security. Utilizing eco-friendly chemistry principles can cause the development of more secure, less polluting choices. Producers need to also examine end-of-life situations for their products, advertising recycling or secure disposal techniques to mitigate lasting ecological repercussions.

Including these considerations into item evaluation not only improves company responsibility but likewise lines up with boosting customer need for environmentally friendly products. Chemical Products. Ultimately, a comprehensive evaluation of ecological effect is essential for fostering sustainable manufacturing practices

Implementing High Quality Control Procedures

The dedication to lasting methods and check it out environmental safety naturally encompasses the execution of top quality control actions within making processes. Quality control is important for making sure that chemical items fulfill predefined criteria and guidelines, therefore securing not only product effectiveness however likewise ecological stability.

To properly apply high quality control steps, producers must embrace a systematic method, starting with the facility of clear top quality benchmarks. This includes defining specs for raw products, intermediate items, and last outputs. Routine testing and examination protocols need to be instituted to keep an eye on conformity with these standards throughout the manufacturing cycle.

Educating and involving staff in high quality assurance methods is equally important. An educated labor force adds to a society of top quality and liability, enhancing overall functional performance. Inevitably, strenuous top quality control determines not just make sure compliance however also fortify the brand name's online reputation helpful resources and foster trust among customers, straightening with the overarching goals of sustainability and safety in the chemical production field.

Final Thought

In final thought, the analysis of chemical items demands a comprehensive understanding of regulative compliance, product compatibility, cost-effectiveness, and environmental impact. This guide serves as a vital resource for accomplishing these important objectives in chemical item assessment - Chemical try this web-site Products.

Report this page